|

|

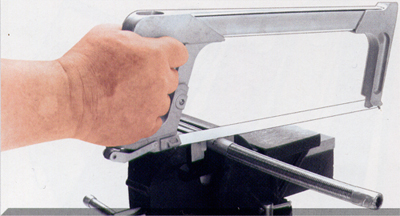

1.

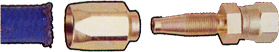

Cutting the Fragola Performance Systems Series 3000

stainless braided hose is easy. Wrap the hose with "Gray" or

masking tape at the length desired. Hose may be cut with a

hack saw, if you have a 32-teeth-per-inch blade, otherwise a

Beverly Shear, radiac, or chop saw will work fine. You want

to keep the braids from fraying. After the cut, carefully

remove the tape and trim from the frayed ends if necessary.

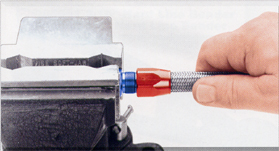

2. Using FPS aluminum vice jaws will help protect the hose

from scratching during the next steps. If there is a concern

about scratching, the hose end may be wrapped with tape for

protection. Place the red socket in a vise, and insert the

hose through the smooth end until the hose lines up with the

bottom of the threads inside the socket. |

|

3. It is

important to mark the outside of the hose at the end of the

socket. This will show you if the hose has "pushed out" of

the socket during assembly, and if so, will leak when used. |

|

4. It

is very important to lubricate the inside of the hose/socket

assembly, and the outside of the cutter threads with any

assembly lube, anti-seize compound, or 30 wt. Motor Oil.

W/D-40 is not recommended! |

|

5. Hold

the hose and not the socket, start the hose on the nipple of

the hose end, with a gentle motion. Continue pushing on the

hose until the threads can be engaged. Some sizes may

require the use of some force to engage the threads at this

point. |

|

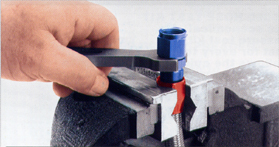

6. It

doesn't matter which portion (the socket or the nipple) is

secure in the vise. Using a suitable wrench tighten the

socket threads onto the cutter. An adjustable "Crescent"

type wrench is not recommended, as it may slip and damage

the outside of the hose end.

7. Tighten until the socket is within .060-.080" of

bottoming out. Recheck your mark, and if it is within 1/16"

of the socket your are OK. If not, disassemble the hose end,

re-cut the hose and start all over again.

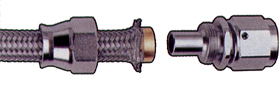

8. Clean the inside of the hose assembly with the clean

solvent. Blow out residue with a compressed air. It is

strongly recommended that you test the hose assembly for

leakage before putting it into service. Be sure to lubricate

the "B-nut" threads before installing on an adapter. |

|

P.T.F.E. Hose Assembly |

|

You may cut the hose in the same method as our 3000 series hose. With the hose cut to the desired length, you

must first slide the "socket" onto the hose.

Next you must open up the braiding in order for the

"olive" to slide over the PTFE liner. Our #900065 PTFE Braid

Spreader works well in this application. The

braid must be spread sufficiently so that small shoulder

inside the "olive" rests against the cut end of the PTFE

liner.

If you used our #900065 Braid Spreader, the nipple end

will have already resized the PTFE liner, which may be

squashed from the cutting operation. If not, you must insert

something in the end of the PTFE liner to bring it back to a

round shape (and ice pick works well for this operation)

|

|

|

Push-Lite Hose Assembly |

|

Soften

the end of the hose slightly in boiling water. Then oil the

hose end nipple.

Clamp the hose end in a vise using our #900061 Aluminum Vice

Jaws, and in one motion push the hose over the barb. The fit

is tight on purpose, as it is the only method of hose

retention. |

|

Power Steering Hose

Assembly |

|

You may cut the hose in the same manner as our Series 3000

Race Hose, but it is not necessary to tape the end prior to

cutting.

Install the "socket" over the cut end of the hose. Some

twisting may be required to get the "socket" to the desired

position with the hose seated against the bottom of the

socket.Clamp the hose and socket in a vise using our

#900061 Vice Jaws. Oil the tapered nipple with some form of

motor oil/assembly lube, and screw the fitting all of the

way in, until the socket seats on the fitting shoulder. Blow

out with compressed air to remove any assembly residue. |

|

|