| Congratulations

on buying the finest A-N hose and fitting products ever

made! Please be certain to properly assemble the hose &

ends. You will find complete instructions on pages 42 &

43.

When doing any plumbing job, be sure to route

the hoses far away from heat sources like the exhaust

system. Secure the lines at various points to retain them

from moving.

Use a few drops of motor oil on the

threads and the seat area of the hose end. The seal is made

on the 37 degree flare. Be careful not to over tighten

the hose ends so as not to damage the flare.

A word about anodizing...At Fragola

Performance Systems, we use a process that is called

"bright-dip". The anodizing process is not an exact science

like painting. The colors will vary from batch to batch,

plus the sun, heat, and time will cause some fading. Various

alloys of aluminum will anodize with different hues.

Where engineering counts! Hose ends may

look alike, but at Fragola Performance we take them

seriously. We have spent years researching, testing, and

generally perfecting this 50-plus-year -old design. We feel that

this catalog contains the finest hose ends made. PERIOD!

|

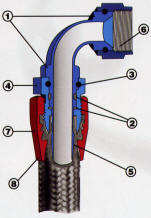

1. Unique one-piece design eliminates

two braze joints, eliminating the potential for leakage, and

improving flow and appearance.

2. Two Viton "O" rings form a redundant seal to ensure

no-leak service for the life of the hose end.

3. Stainless steel lock wires prevent galling and assure

smooth operation.

4. Wider wrenching surface for a no-slip installation.

5. Tapered nipple for easy alignment and installation.

6. "J" gauge threads for increase strength.

7. Bright dip anodizing for a show quality finish.

8. Improved entry angle on the socket eases hose

installation. |

3000

Series Race

Hose Ends

Where engineering counts! Hose ends may look

like simple devices, but at FPS we take them very

seriously. We have spent several years researching,

testing and retesting to perfect the production of

what we feel is the finest hose end available.

Period! We hope that you will agree.

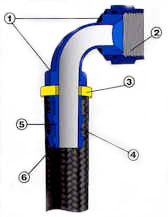

1. Unique ONE-PIECE design eliminates two brazed joints, minimizing

potential leakage, improving flow and appearance.

2. Two Viton®

"O" rings form a

redundant seal to ensure no-leak service for the

life of the part and are impervious to fuel, oil and

coolant.

3. Stainless steel lock wires to prevent galling and

provide long service.

4. Wider wrenching surface for a no slip

installation.

5. Tapered nipple for easy alignment and

installation.

6. J gauge threads for increased strength and

durability.

7. Bright dipped anodizing for a show quality finish.

8. Improved entry angle on the socket, allows for

easy installation.

All

Hose Ends are manufactured from aerospace quality

aluminum and machined to mil spec tolerances. |

8000

Series Push-Lite Race Hose Ends

Where engineering

counts! Hose ends may look like simple devices, but

at FPS we take them very seriously. We have spent

several years researching, testing and retesting to

perfect the production of what we feel is the finest

hose end available. Period! We hope that you will

agree.

1. Unique ONE-PIECE design

eliminates two brazed joints, minimizing potential

leakage, improving flow and appearance.

2. The correct A-N specified

"J-Thread", for ease of installation,

and trouble-free reuse.

3. Lightweight polymer cap provides positive

stop for hose installation, and cover cut end of

the hose.

4. Hose barb dimensions per S.A.E standards.

5. Bright dip anodizing for a show quality

finish. All Push-Lite hose ends are manufactured

from aerospace quality and machined to milispec

tolerances.

6. Tapered nipple for easy alignment and

installation.

All

Hose Ends are manufactured from aerospace quality

aluminum and machined to mil spec tolerances. |

|

|

|